UV Long Optical Path Steralization System

We have created a system that overwhelmingly enhances the effects of the conventional air sterilization method using ultraviolet rays. (Pat P)

Even equipped with a small light source with a small capacity, reliable and ultra-high efficiency sterilization can be expected.

In addition to configuring electrical appliances, it can be installed in the return air or air supply ducts to sterilize the air conditioning system.

Alternatively, a safe indoor air sterilization system can be configured as part of the indoor fixure.

Virus Blocking Respirators

We invented 2 types of respirators to (possibly) block virus, named "Ultra High Performance Filter Respirator" and "Air Flow Electrification Respirator".

Is it really possible to "block viruses"?

View

Ultra High Performance Filter Respirator

Actually, we have not developed ultra high performance filters, but invented respirator structure that can house and accommodate conventional high performance air filters with high permeation resistance to the respirator.

The respirator structure realizes ultra high performance by expanding filtering area of the adopted high performance filters such as ULPA designed for clean rooms, etc.

View

They say, high-performance mask respirators such as N95 or N100, which can collect fine particles, have large breathing resistance (pressure loss) and make it difficult even for medical staff to wear them for a long time.

The "Ultra High Performance Filter Respirator" would theoretically reduce this permeation resistance to only one severalth and make it possible to be worn for a long time. Furthermore, the structure enables to employ ULPA filter media that is special type of HEPA filter medias for HVAC use and conventionally applied for advanced infection-prevention areas requiring blocking most part of viruses.

We assume respirators that can be worn for a long time without getting tired and that block most of the viruses like "Ultra High Performance Filter Respirator" would alter the situation to cope with COVID-19 dramatically, especially in the medical field.

Mechanism of Ultra High Performance Filter Respirator

The core of the device is the structure expanding the filtration area to reduce the total air-flow resistance (pressure loss of the permeating air) for breathing.

Ultra High Performance Filter Respirator consisting of N95 or Higher

The "Ultra High Performance Filter Respirator" can be constituted by stacking several existing N95 to N100 products with some other parts.

View

"Ultra High Performance Filter Respirator" can be composed of various types of filters, but can also be realized by stacking N95 (or higher) masks.

In this case, the filtration performance is not significantly improved compared to the N95 (or higher) alone, but the resistance during breathing can be greatly suppressed.

Note) Filtration performance may be relatively reduced (although it may be improved overall as a result of the increased filtration area and reduced face wind velocity). However, since the filtration performance is enough high in many situations to use N95 (or higher), we suppose a slight decrease of the performance would not be assumed to matter very much in comparison to easing the use.

not cosplaying mickey mouse

The ready-made N95 (or higher) mask is thinly molded, so it won't be too bulky when stacked.

However, since it has a certain thickness, it seems to be cute.

Here, the structure using 3 sheets of N95 (or higher) is shown. The three sheets of N95 (or higher) sandwich breathable ventilation sheets of open-cell resin (sponge-like porous resin) or felt.

Assembly diagram

The ventilation sheets allow air to flow freely between N95 (or higher) gaps. Those sheets have airtight packing parts formed by infiltrated with an elastomer or low-resilience elastic material. The inner sheet has it at the center and the other in the outer periphery. This airtight packing keeps the stacked N95 (or higher) masks in close contact with each other to prevent air leakage. The outermost N95 (or higher) has an exhaust valve in the center, and the others have a vent hole in the center.

Since air freely flows in the space around the wearer's mouth, in the outside space of the mask, in the ventilation holes, and in the ventilation sheets, the air pressure is approximately equal everywhere in each area where these connect directly one another.

The space where the pressure is approximately equal is divided into the purple range and the light blue range shown below.

Air flow and equal pressure area diagram

The purple range and the light blue range in the figure are separated by N95 (or higher) and the airtight seal.

Air in the purple range is sucked into the blue range through the 3 N95 (or higher) layers.

In this way, the outside air permeates N95 (or higher) and is filtered to become clean air.

Since the outside air is filtered by permeating three N95 (or higher) masks in parallel way (it means filtering area is expanded to approx. three times), the amount of air that can be filtered at the same pressure is about three times that of one N95 (or higher).

And also, when the wearer inhales the required amount of air, the speed at which the outside air permeates N95 (or higher) (surface wind speed) is approximately 1/3.

At this time, the resistance (pressure loss) when the air permeates N95 (or higher) becomes about 1/3 to 1/9 (depending on the flow velocity and the fiber structure, it will be proportional to the 1st to 2nd power of the wind speed). It means the structure can greatly reduce the force and the energy required to draw in air.

Generally, a respirator with an exhaust valve is intended to prevent infection of the wearer from the outside, and is not intended to actively prevent infection of the others form the wearer. In order to make the wearer's breathing easier even a little, the exhaust valve is used to exhaust the exhaled breath to the outside with almost no resistance. However, most of the direct splashes of the wearer's cough and sneeze can be blocked as a mask, so the effect of preventing infection from the wearer may be expected for a certain degree. In addition, it may be better to apply gauze or the like to the mouth side of the respirator to primarily block the splashes in the breath of the wearer and adjust the humidity in the mask.

Ultra High Performance Filter Respirator using HEPA/ULPA

View

As described above, by increasing the area of the filtration part, it is possible to reduce the total forece of air permeation resistance. It means, it provides another benefit. Ultra high performance filters such as ULPA, which is applied for advanced clean room/operation room HVAC system but unavailable for conventional respirators due to the large resistance, can be applied for the Ultra High Performance Filter Respirator.

There are several standards and requirements for HEPA (High efficiency particulate air) and ULPA (Ultra Low Particulate Air). According to the English Wikipedia page of Ultra-low particular air referring to IEST practices, an ULPA filter can remove from the air at least 99.999% of particles with a minimum particle penetration size of 0.1 micrometre.

Considering the size of COVID-19 is assumed to be approx. 0.1 micrometre, ULPA would block the most part of the virus.

Configuration with HEPA/ULPA - example 1

Configuration with HEPA/ULPA - example 1

The respirator is to be worn with a restraint net so that it covers the mouth.

In the above figure, the upper and lower ends are shown as if they were cut off for the sake of explanation, but it is better to use clip or fastener to closes them so that you can disassemble them for easy maintenance.

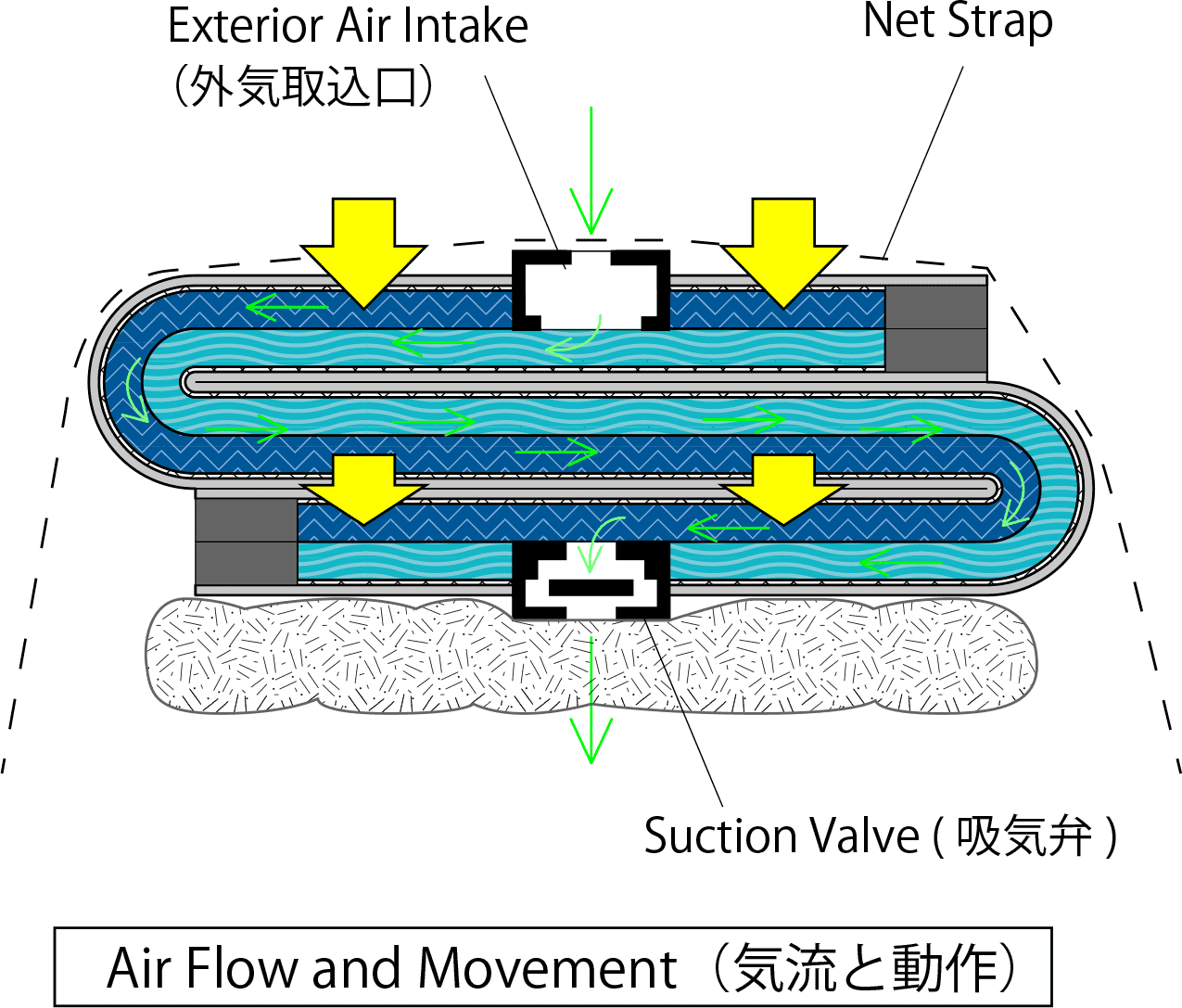

Airflow diagram of respiration

In this example, the integrated filter is folded back to form four layers of filtration.

Configuration with HEPA/ULPA - example 2

Tailored to fit the face

An example of forming with cut pieces of filter media. Since the ULPA filter medium has low strength, it is considered more appropriate to join the cut sheets divided into multiple parts and form them into a three-dimensional shape rather than bending the one constructed by stacking two-dimensionally in layers and fitting it to the mouth. Also, it may be better to reinforce with other fibers that serve as binders and covers.

General notes with HEPA / ULPA

In the case of using glass wool filter media, in order to prevent the fibers from sticking to the skin, cover them with a breathable film or binder material to prevent the fibers from directly touching the wearer's face.

In addition, it is necessary to perform a treatment that does not scatter the glass wool due to movements such as wearing and breathing.

As mentioned above, it is important to take sufficient measures and studies to prevent the wearer's health damage.

Air Flow Electrification Respirator

A respirator taking advantage of air pressure fluctuation due to the wearer's breath to generate static electricity, which charges the filter and adsorbs particles.

By lining the aluminum sheet or mesh, it is expected that a capacitor is formed and a stable electric field can be maintained. Applying brass instead of aluminum may be better because it has bactericidal effect. (Brass net was used for the core material of masks in the Meiji era in Japan.)

Note) By charging the filter, in principle it is expected to adsorb even fine particles such as viruses, but much part of the field of static electricity has not been clarified yet. So we suppose some R & D and study is necessary for productization.

View

Collecting particles by electricity

Particles in the air can be collected by using the Coulomb force between positively charged substance and negatively charged one.

The outline and mechanism of the current methods and devices for collecting particles using electricity are explained below. Also, problems of existing respirators aiming the effect of electricity to collect particles are shown as well.

View

In huge plants, usually electrical precipitators are installed for cleaning exhaust gas. The mechanism is: a high voltage is applied to the tip of the needle to generate a corona discharge, and the dust passing through the surrounding air is charged to generate a Coulomb force to the electrode on the downstream side and attract it. Even fine particles can be removed, but in general, this is a very large-scale facility.

On the other hand, instead of corona discharge, there is also a compact device that ionizes the particles with an ionizer and adsorbs them to the electrodes, which is not very rare as one of the general air cleaner systems.

However, all of these methods require high voltage, so a power supply, a transformer, a discharge device, etc. are required, which is too large for mask application.

By the way, particles floating in the electric field can be attracted to either positive or negative electrodes without applying corona discharge or ionizer as described above (even the Coulomb force is smaller).

The particles are either positively or negatively charged originally, or a charge appears on the surface due to dielectric polarization in a strong electric field, so they are attracted and adsorbed by the opposite electrode.

There is an electrostatic filter that uses this mechanism, and it is also widely used in masks. Instead of using an electric power source to generate an electric field, this uses a non-woven fabric called electret, which fixes charged static electricity like a magnet.

However, in recent years, negative experimental data is shown that the electret filter's ability to collect particles is not so high.

We would attribute the reason to the surface voltage which is at most 2-300V according to the data. The voltage might not be high enough to keep on holding the captured particles.

Fundamental mechanism of "Air Flow Electrification Respirator"

Based on the mechanism of collecting particles by electricity as described above, we have devised a innovating mechanism to collect particles by generating static electricity by the air flow of the wearer's breath and charging the filter.

Static electricity is generated by rubbing different types of materials together, and the charged static electricity can actually reach several thousand volts.

Generally, we try to avoid or eliminate static electricity, but in some cases, we take advantage of it. For example, a duster generates static electricity when you clean something with shaking move and charges itself to adsorb particles.

"Air Flow Electrification Respirator" also generates static electricity to charge the filter and adsorb particles. Basically, it utilizes the move of diaphragm part of the mask actuated with fluctuation of air pressure caused by breathing.

Since it uses static electricity, it is mainly used in a constant low humidity environment. Generally, it is said that static electricity is likely to occur when the humidity is within 40%, but we assume, the amount of charge and the strength of the voltage and electric field obtained should depend on the balance between electrification and discharge. So we believe that the necessary electric charge including the case where the voltage is not felt by the human body (it is said that static electricity of 1kV or less is not felt by the human body) can be obtained if humidity proof structure shown later applied.

However, since exhaled breath contains a large amount of water vapor, if it passes through a filter to be charged, the static electricity charged in the filter will escape in the air or on the damp material surface. So exhalation is basically supposed to be released outside after once filtered with gauze put inside.

We devised high-humidity proof type as well, but the structure is slightly complicated and bulky.

High-humidity proof type with complete airtight electrification mechanism

Material of electrification part

Static electricity can be generated by combining positively charged materials and negatively charged materials with each other and repeating contact, peeling or rubbing. Specifically, one side is made of wool or nylon, which tends to be positively charged, and the other side is made of polyethylene or polypropylene, which is easily negatively charged.

If the filter is composed of microfibers, it would provide great effects including physical blocking of particle. In the case of mixed fiber that combines these materials, it might be microscopically easily charged, but the voltage of the static electricity is possibly not so high. Further R & D would be required to prove.

Mechanism of electrification part

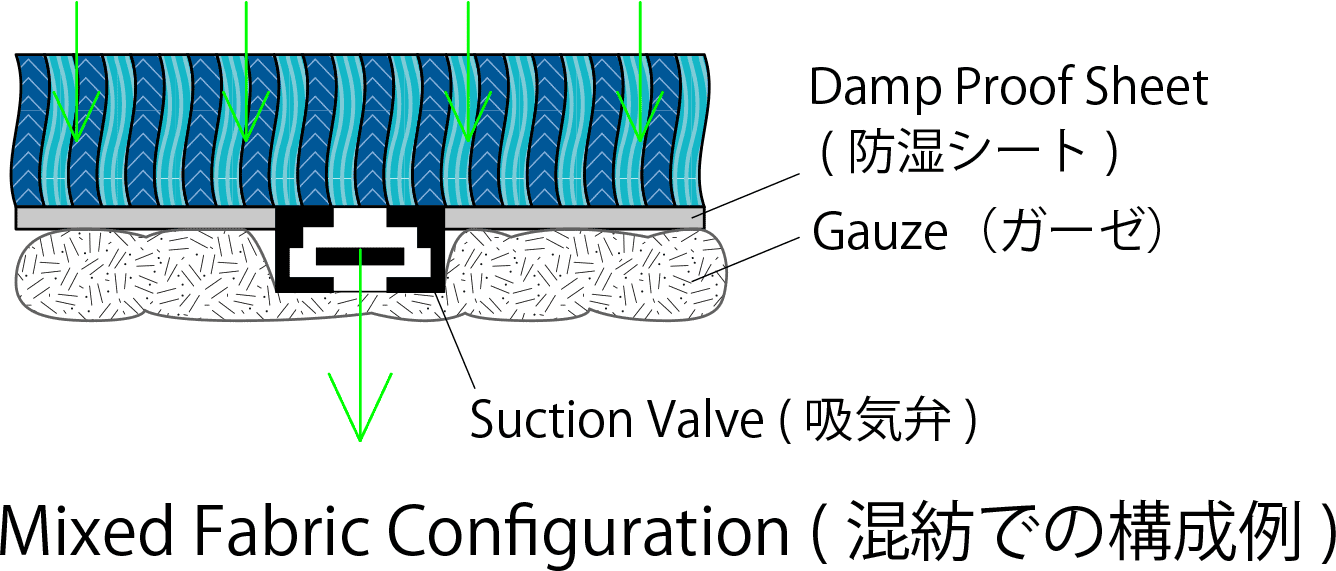

The diaphragm that covers the wearer's face expands and contracts due to pressure fluctuations caused by the wearer's breathing.

By utilizing this move, it is possible to generate static electricity by contacting and detaching the electrification materials, or by rubbing the electrification materials each other in shearing direction.

The specific mechanism for generating static electricity is described below.

Contact and detaching mechanism

It is considered that mentioned electrification materials being contacted each other can generate static electricity only by repeating compression and relaxation, because microscopically contact, detaching and friction are performed within the fiber. However, depending on the material conditions, it may be more effective to contact and detach them in macroscopic way.

In this case, by sandwiching a spacer such as a grid between the electrification materials as shown in the figure below, the electrification materials can normally be kept separated from each other, and contact by being pressed to deform.

Note) The spacer material is an electrically neutral insulator that does not easily charge.

By repeatedly contacting and detaching the materials, static electricity is generated and electric charges are accumulated.

By accumulating electric charges, the surface charge / potential rises, the electric field between these materials becomes stronger, and the passing particles are adsorbed and collected.

Diaphragm in-plane shearing friction mechanism

This mechanism has electrification materials in the diaphragm to be moved in shearing direction to be rubbed against each other.

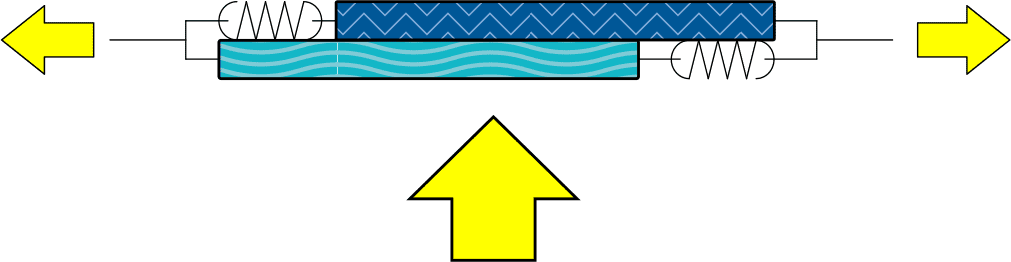

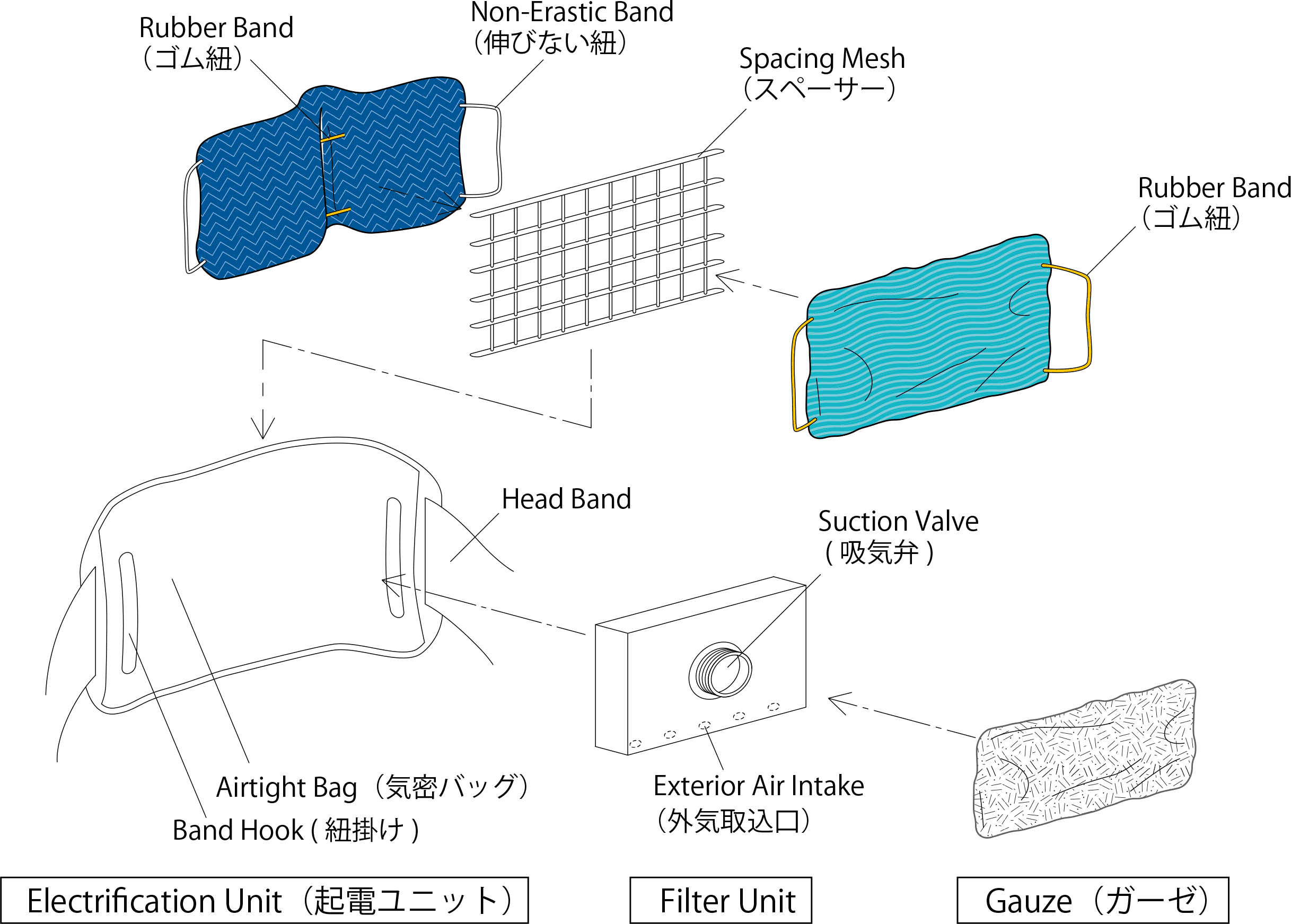

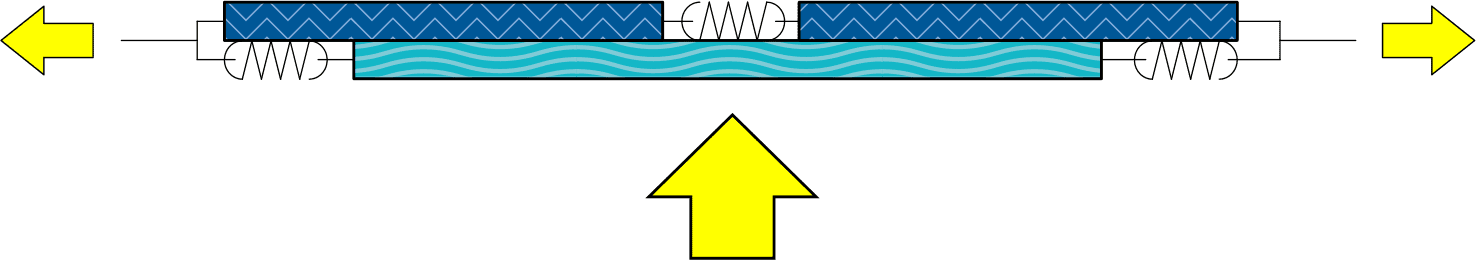

Basic structure

It is a schematic diagram (cross section). Replace the parts shown as springs with rubber cords.

Each electrification material (filter media) is kept pulled with an elastic material (rubber string) on one side and the other with an inelastic material (just string, etc.). The elastic material and inelastic material are set in a staggered manner as shown in the diagrams.

When an external force in the out-of-plane direction is applied to the diaphragm configured in this way, the electrification materials will deform and rub each other.

When the external force is released, the two filter materials will return to their original position by the rubber cord.

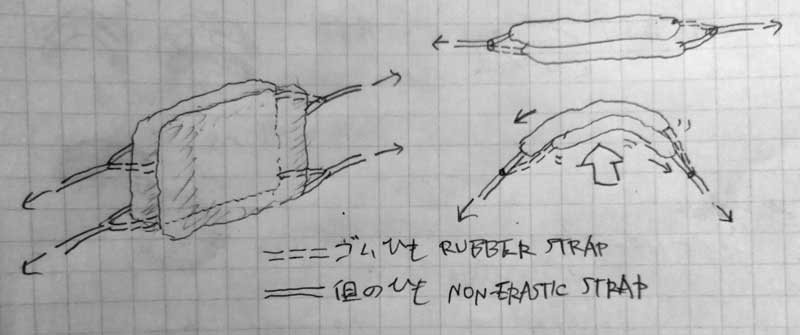

Structure with two friction surfaces

This is an example of a structure in which one filter material wraps the other filter material to form a diaphragm, and two surfaces rub against each other to generate electricity.

As shown in the above figure, the diaphragm is composed of A unit and B unit. The B unit is pulled with elastic string(parts marked with "弾", rubber band, etc.) on the left side and the non-elastic string (marked with "固") on the right side.

On the other hand, the A unit is towed with an non-elastic body on the left side and an elastic body on the right side.

These tensed strings and rubber bands should be towed together at each of upper left, lower left, upper right, and lower right and connected to the ear hooks or straps worn on the head.

The diaphragm is bent to the out-of-plane direction

When the diaphragm is deformed by the external force caused by the wearer's breathing, the A unit and the B unit are displaced in the shearing direction and rub against each other to generate static electricity, as shown in the sketch above. In this structure, the same side of polarization may be supposed to appear on the front side and back side of the inner B unit. As it may cancel electricity each other due to dielectric polarization, it would be unsuitable depending on the material and layer structure.

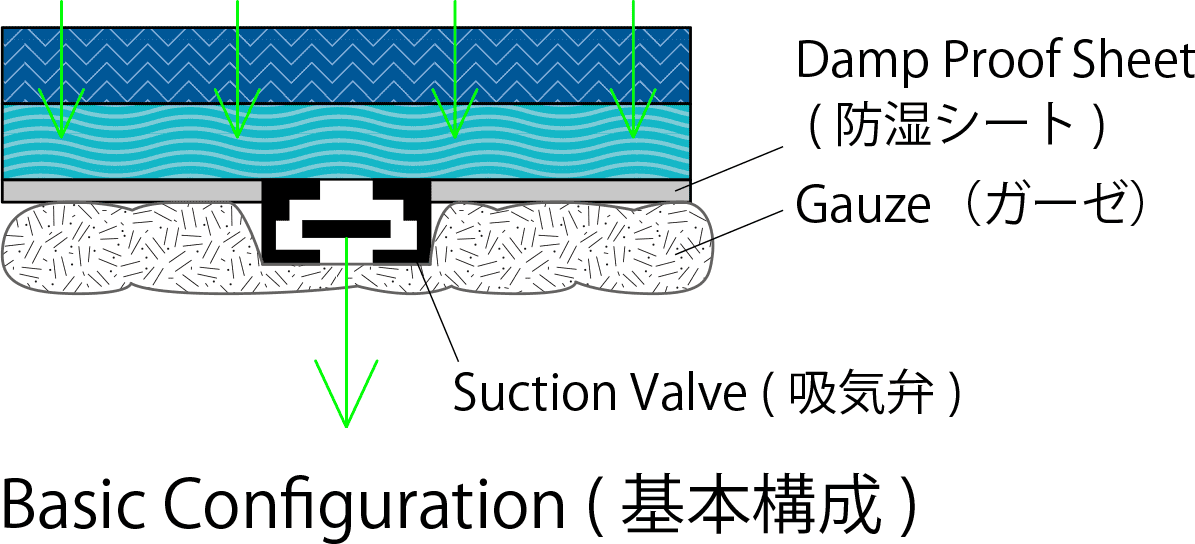

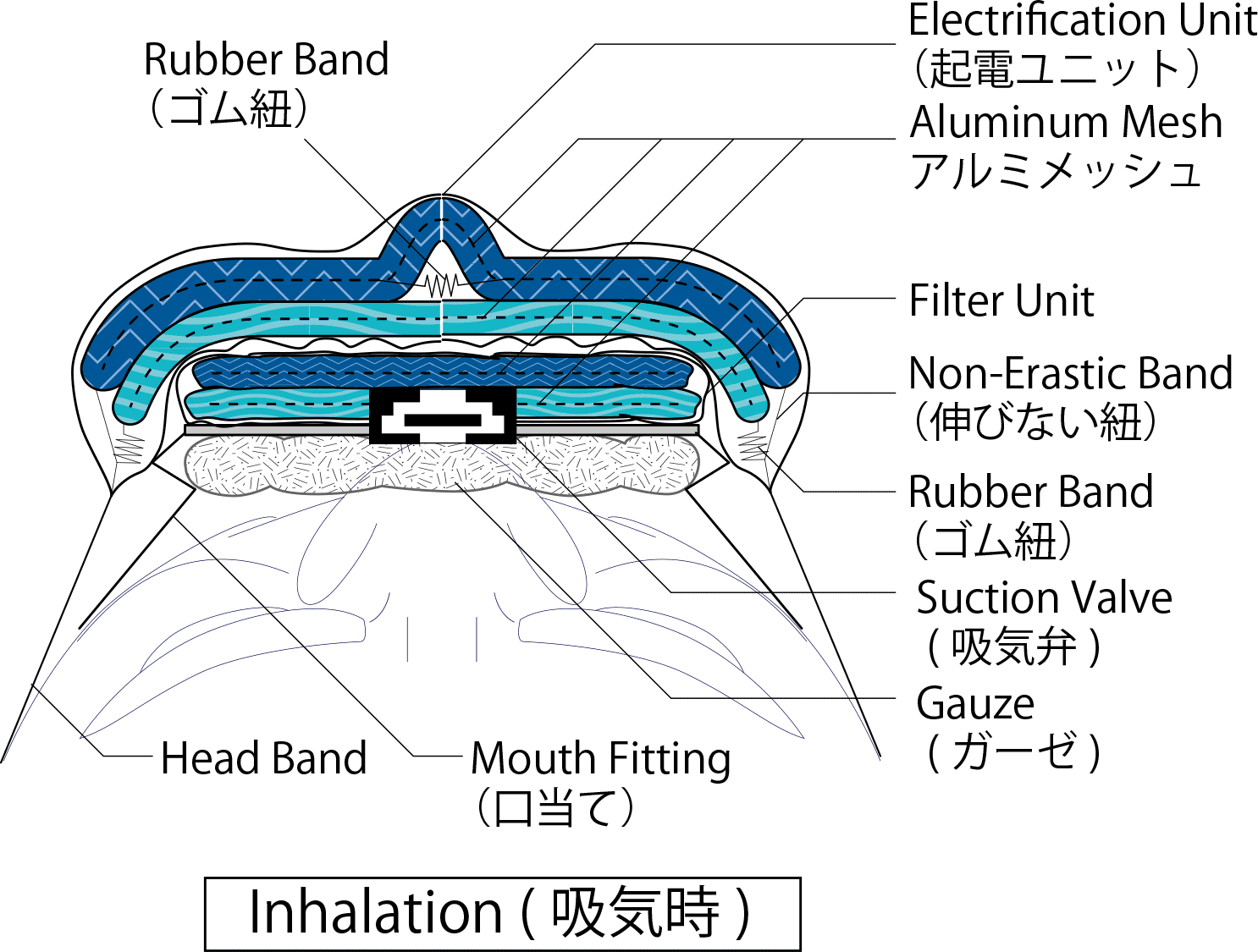

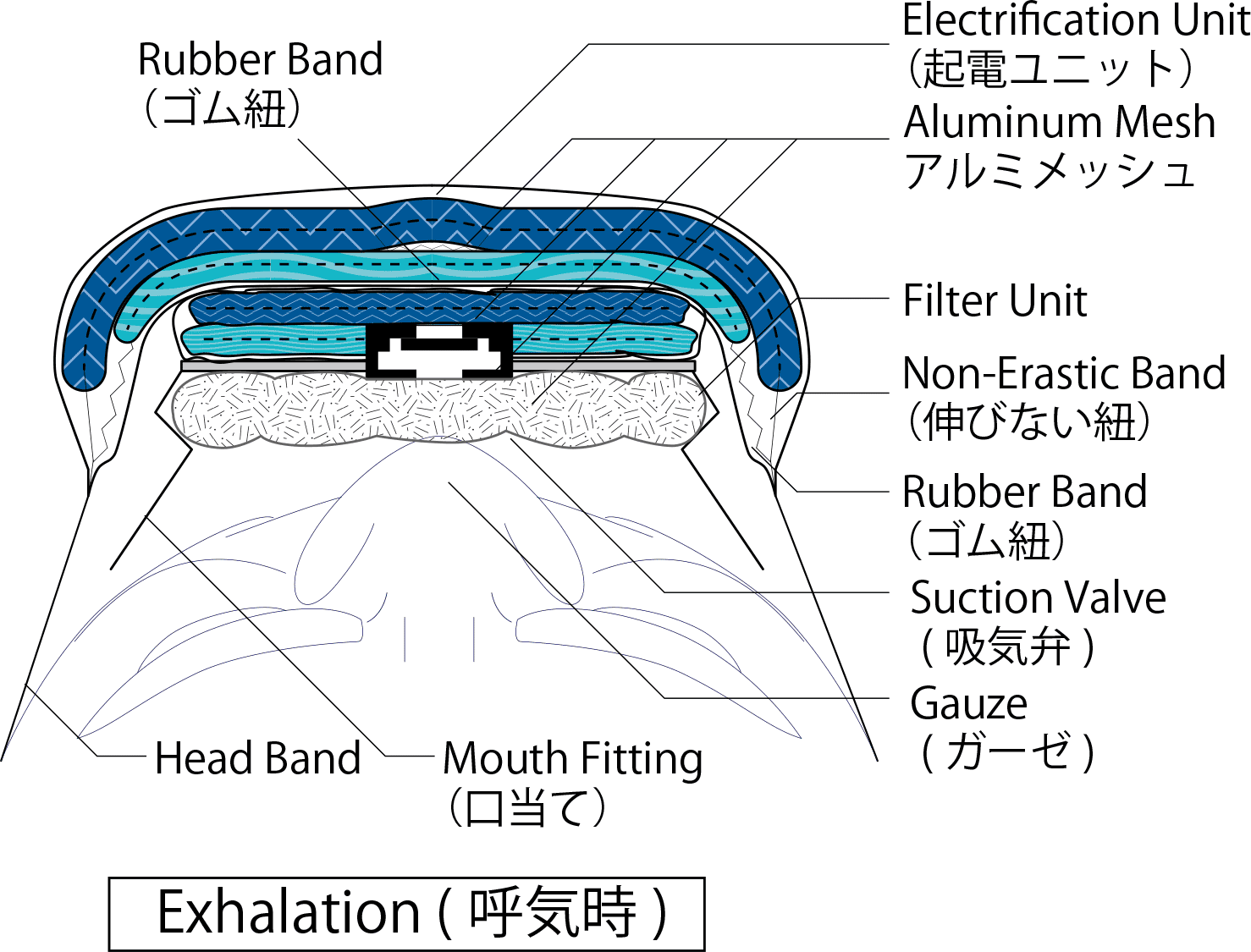

Basic constitution of filter

The Air Flow Electrification Respirator generates static electricity by the above-mentioned mechanism. However, since static electricity is difficult to be charged in a high humidity environment and exhalation contains a large amount of water vapor, exhalation should be basically displaced to the outside without being filtered by the electrified filter.

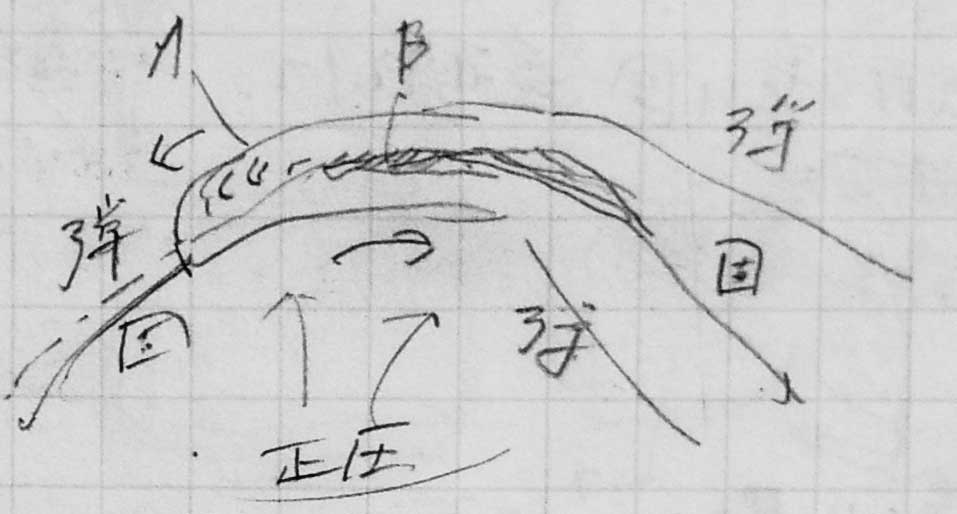

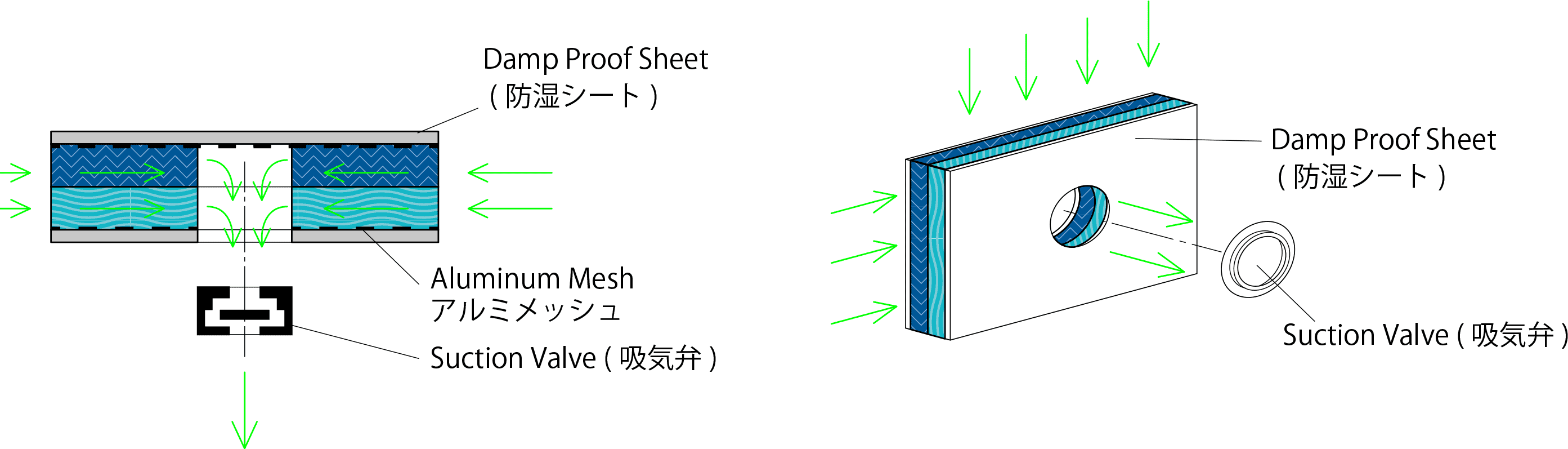

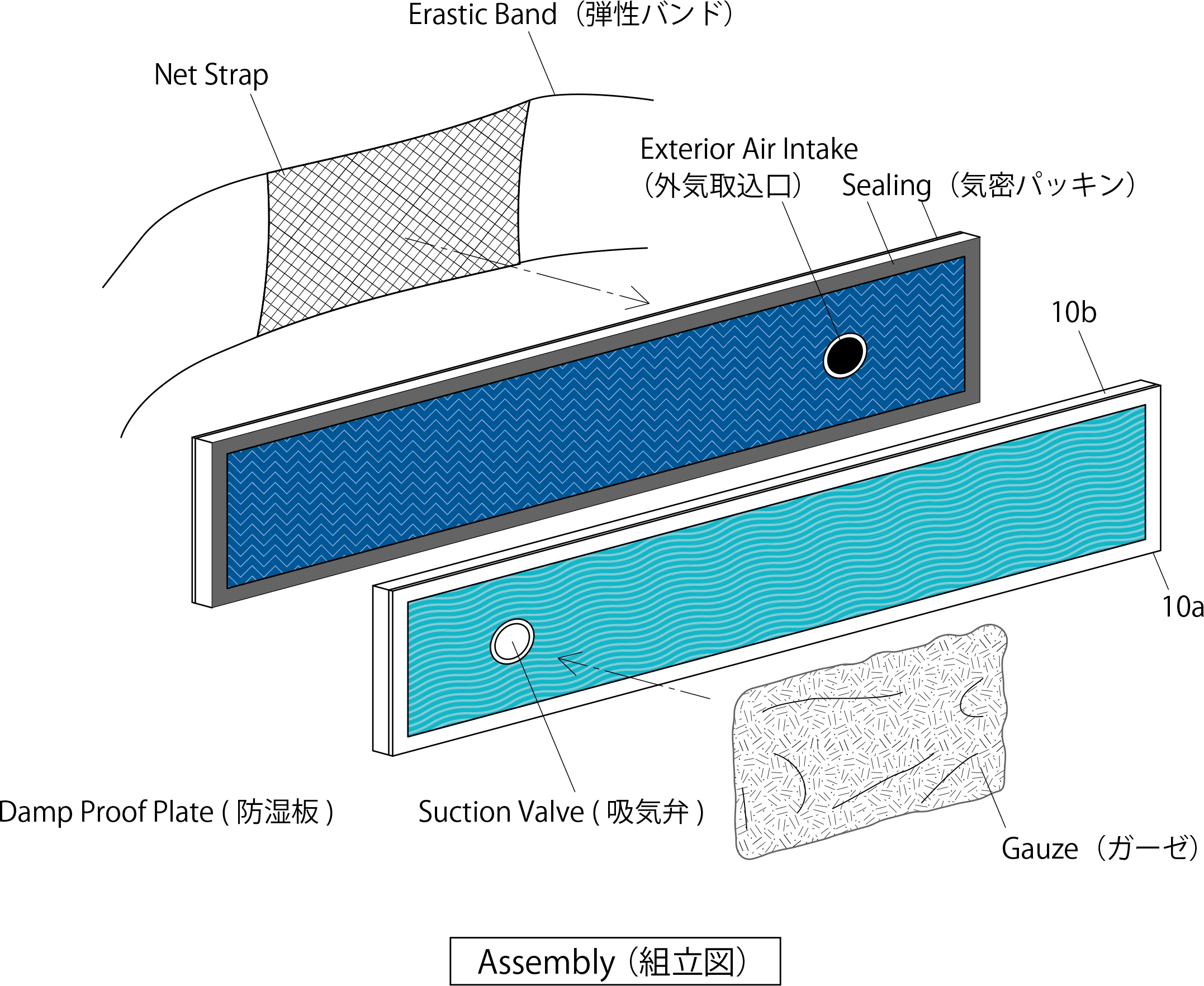

Above diagram shows the basic configuration of the filter part of the respirator.

The damp proof sheet shuts off the electrostatic charging filter and the wearer's mouth, and only the suction valve, which allows airflow in one direction, passes through the sheet. With this structure, the exhalation of the wearer does not pass through the filter, and the filter can be kept dry.

Note) the suction valve can be a valve equivalent to a exhaust valve attached to a conventional N95 (or higher) mask, etc. installed in the reverse direction.

The electrification part (filter) can be mixed fabric in electrifying combination of fibers.

In the case of microfibers or fine fibers mixed in microscopical level, the surface potential (maximum value) might not be enough to retain adsorbed particles. It is a theme for further R & D.

Respirator example

An example of respirator structure that applies the basic configuration of electrification filter to generate electricity by the in-plane shear friction mechanism of the diaphragm.

Instead of the moisture-proof sheet, a resin plate which is elastic but approximately incompressible in in-plane direction is applied. The positive pressure on the mouth side causes the mask to swell to the outside during exhalation and it leads to a slippage between the electrifying materials composing the filter and electrify.

Exhaled air is discharged from the side of the mouth cup that covers the wearer's mouth and nose, but an exhaust valve can be installed separately. In addition, droplets of the wearer's cough and sneeze is simply filtered by the gauze not to splash directly to the outside.

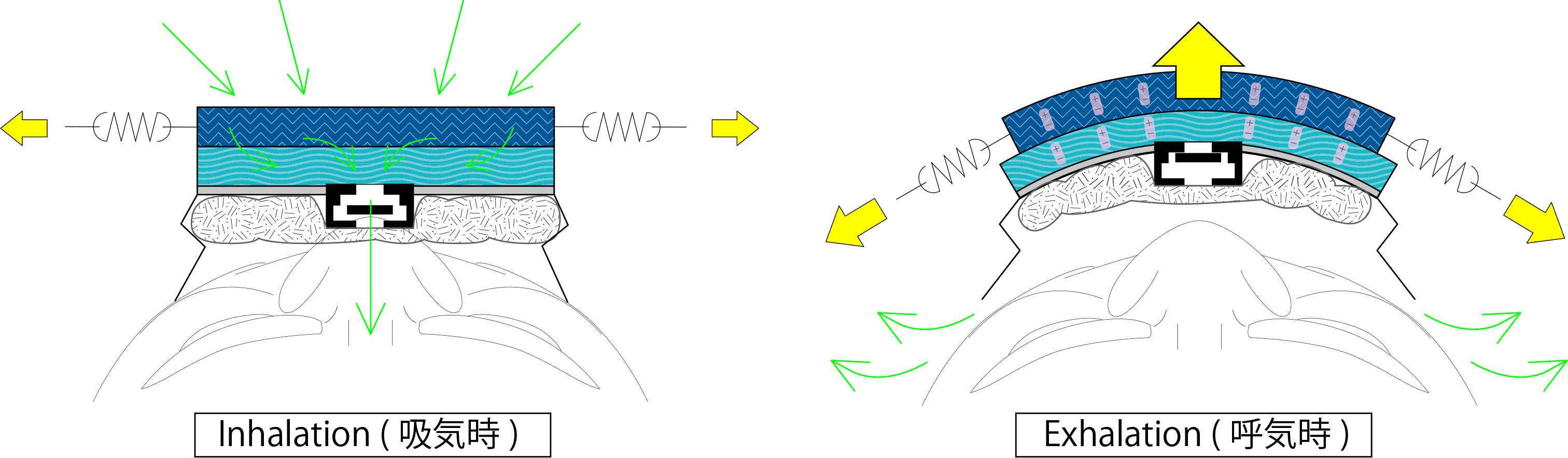

Lining of conductive sheet

We assume that lining a sheet conductor such as an aluminum mesh or an aluminum vapor-deposited sheet on each of the electrifying materials may form a capacitor and store a larger electric charge.

We guess there is not a few who have an experience causing a lot of static electricity by using multiple blankets or rugs that sandwich aluminum sheets for heat insulation utilizing the reflection effect of radiant heat, and by sandwiching blankets of different materials between them.

The main reason for lining the conductor is to aim at the effect of such charging and to form a strong surface potential and electric field.

Since the mesh allows air to pass through, the filter can be configured to allow airflow to pass through in the out-of-plane direction for filtration.

However, as the mesh has a small conductor surface area, the required amount of charge may not be secured. In this case, perforated metal mesh can be substituted for wire mesh.

In the above diagram, the aluminum mesh layer is formed on the damp proof sheet, but the layer and the sheet can be substituted for an aluminum vapor deposition sheet.

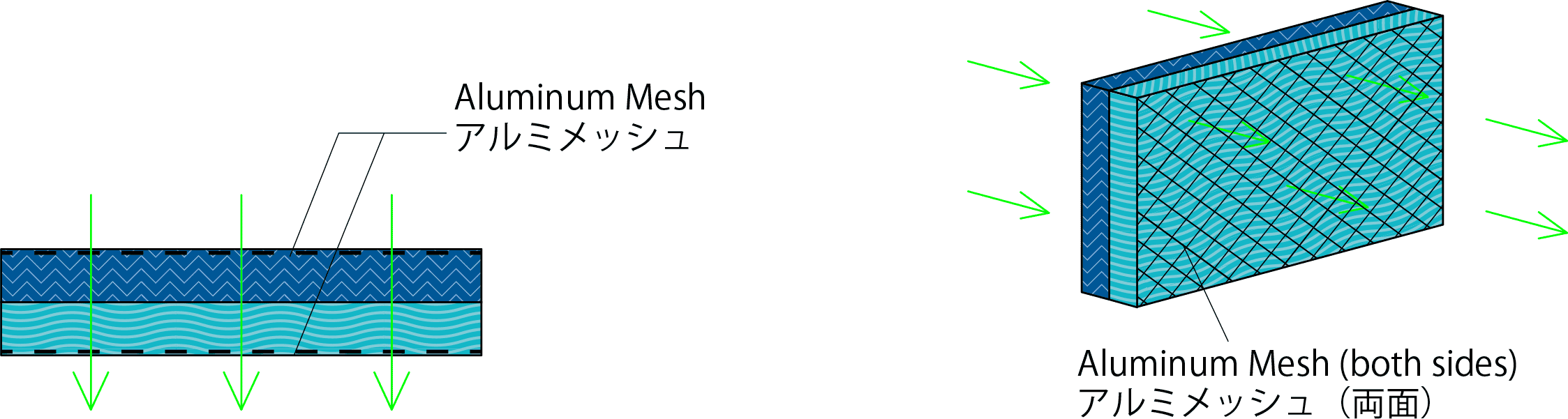

This type of structure is applied to shut off the electrification material completely from the wearer's exhalation, or as a dedicated electrification unit sealed with dry air in a damp proof bag.

Since both sides are covered with damp-proof sheets, outside air is taken in from the peripheral edges and is filtered in the in-plane direction. Filtered air is supplied to the wearer through the central ventilation hole and the suction valve.

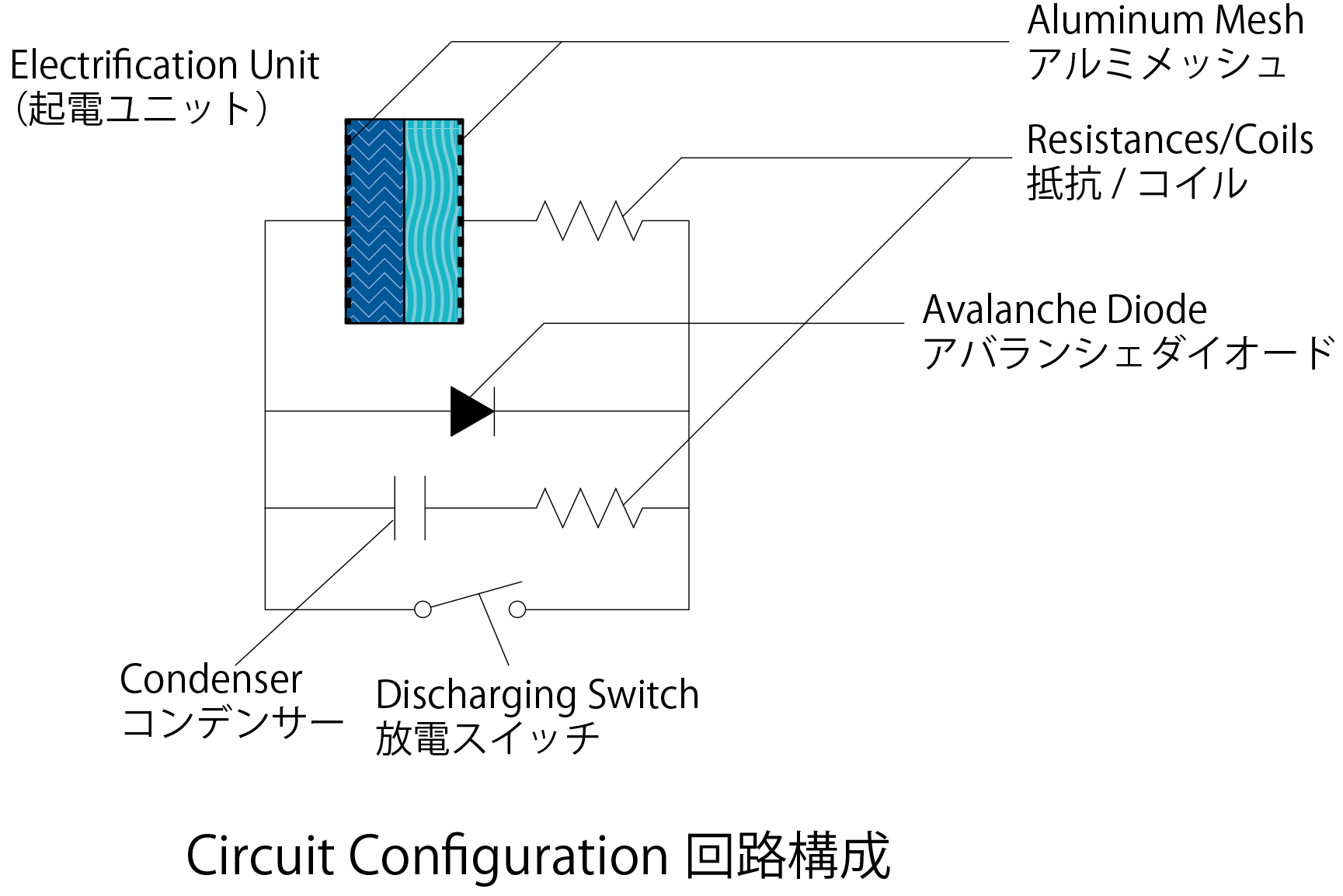

Regulating of charging voltage

Lining the electrification materials with conductor sheets, a electrical circuit can be configured by wiring. The configured circuit can regulate the charged voltage and the amount of electricity, and provides benefits such as safety and maintenance of particle collection capability.

The components that make up the circuit provide the following functions:

- Capacitor: As a charge reservoir, it prevents the loss of charge due to momentary discharge, maintains a constant voltage, and enables stable collection of particles.

- Resistance or coil: Prevents overcurrent due to discharge or short circuit for safety, and slows down the voltage drop, making it possible to collect particles stably.

- Avalanche diode: Configures a constant voltage circuit that prevents excessive voltage to prevent the wearer from receiving an electric shock.

- Discharge switch: Discharges the electricity charged in the circuit by short-circuiting for maintenance and cleaning.

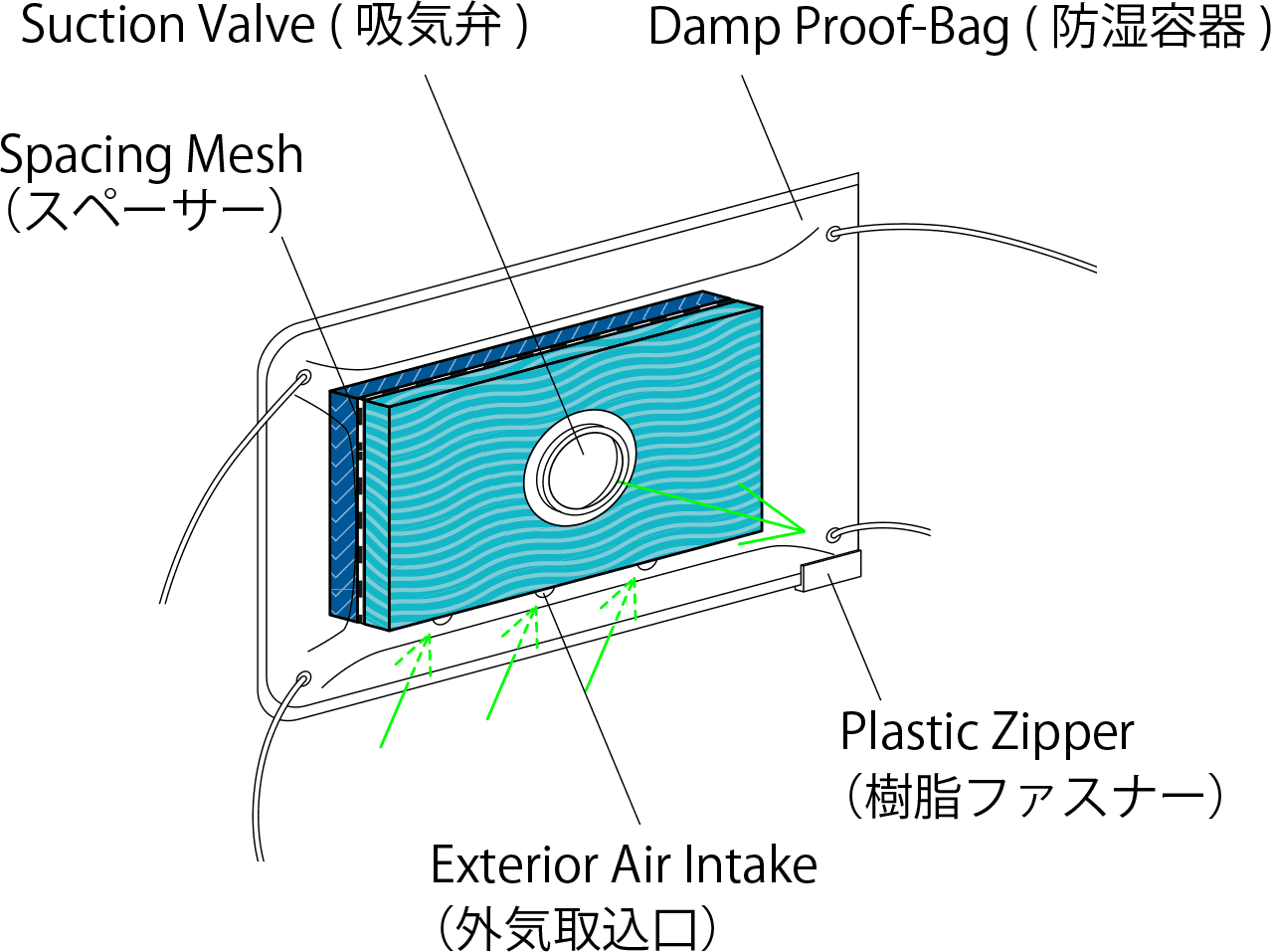

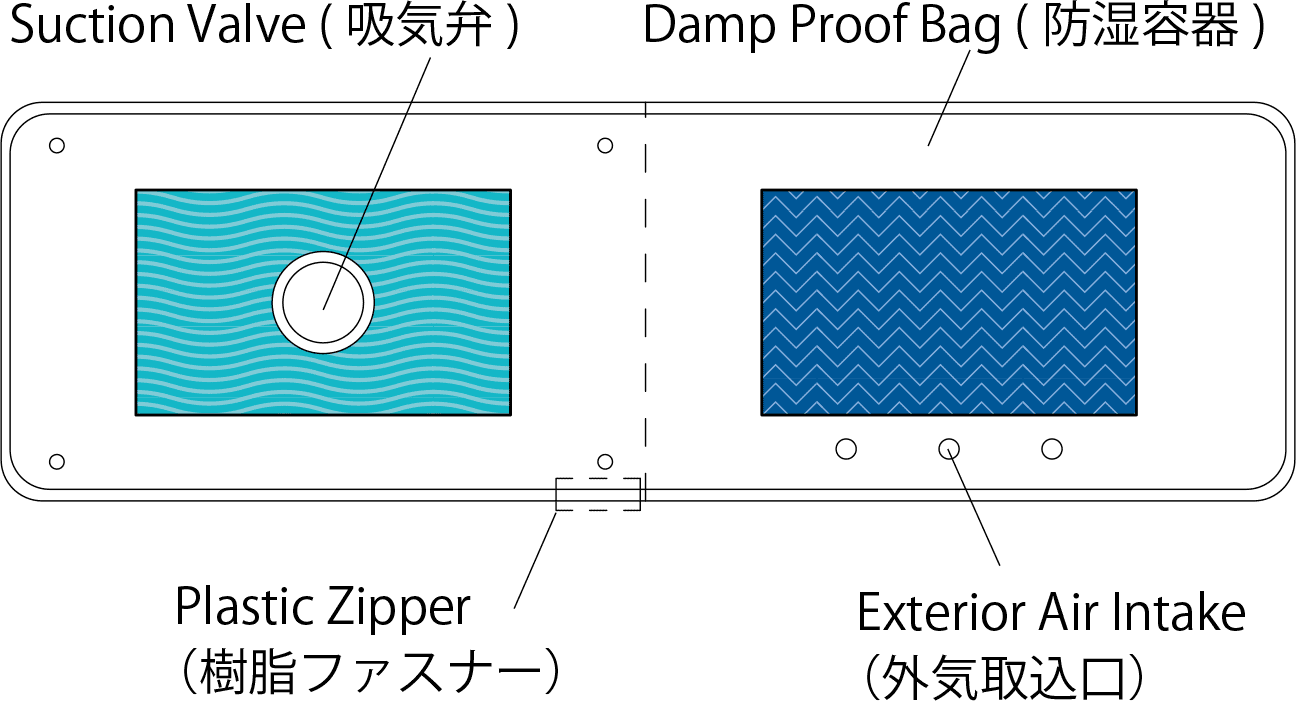

Damp proof type example-1

This is an example of electrification filter unit whose filter is covered with a damp-proof bag to prevent a decrease in the amount of charge due to the expiration of the wearer's breath, and to secure charging static electricity.

The filter is housed in a damp proof bag that can be opened and closed with a plastic zipper.

When the wearer inhales, the outside air is taken in from the exterior air intake, flow through the filter from the circumference edgeds, and is supplied to the wearer through the suction valve.

By narrowing the area of the openings of the exterior air intake in comparison to the area of the opening of the suction valve, air pressure in the damp proof bag can be made negative with a certain strength or more. It makes the bag shrink and compress the electrification filter inside it.

When transitioning from inhalation to exhalation (exhaust), the suction valve closes and the bag swells due to the restoring force of the compressed filter and the openings of the exterior air intake.

In this way, the electrification filter inside the damp proof bag can be repeatedly compressed (contracted) and restored to generate and charge static electricity.

When not in use, the plastic zipper can open the bag for maintenance and cleaning.

Damp proof type example-2

This is an example of a structure that can lengthen the flow path by a filter. This may be effective structure when using a filter with a low fiber density.

As in the previous example, repeatedly compressing and restoring by the wearer's breath charges static electricity .

Easy for maintenance and cleaning by disassembling.

Damp proof type example-3

This is an example of a structure that enables effective use even in a more humid environment by separating the electrifying part and the filtering part.

The size is slightly bulky because of the separated electrification units

In the electrification unit, a spacer is sandwiched between the electrification materials. It is expected as a guide to prevent unpreferable displacement of the materials due to the movement in the shearing direction of each other, and at the same time, as a separator providing the effect of repeatedly detaching and contacting to generate electricity in the movement.

The electrification unit does not filter air, only electrify.

The electrification materials are enclosed in an airtight bag together with dry air, and the airtight bag is deformed by an external force to generate static electricity.

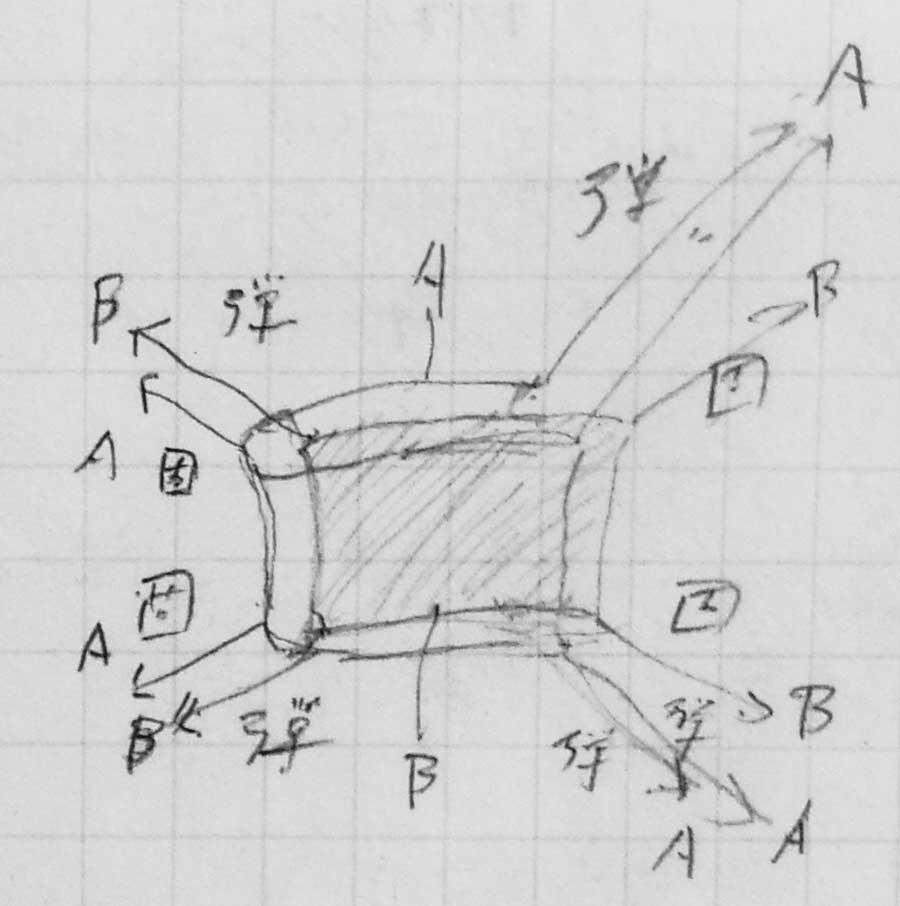

Electrification mechanism is similar to ones described in "Diaphragm in-plane shearing friction mechanism" above, but the configuration below is applied here.

When deformed by an external force in the out-of-plane direction, the electrification materials are displaced from each other and charge static electricity. Replace the parts shown as springs with rubber cords.

As the diaphragm has a symmetrical structure, it provides fit when the aspirator is worn without shifting to the left or right.

The upper material of the diaphragm is divided at the center in the diagram, but the material used in the electrification unit is a continuous stuff in which the center is mountain-folded and both sides of the folding are pulled together.

By moving the filter unit back and forth using the wearer's breath, the electrification unit can be expanded and contracted to generate electricity.

In the electrification unit, when static electricity is generated in the electrification materials, the backed conductive sheets are expected to be charged as well because the dielectric polarization occurs in the materials. By electrically connecting conductor sheets between the ones in the electrification unit and the filter unit, the sheets in the filter unit is also charged to adsorb particles in the air.

The filter unit has an exterior air intake on the bottom.

As mentioned above, static electricity is difficult to be charged in a high-humidity environment, but by housing electrification materials in an airtight bag, it is possible to charge electricity.

The filter materials and the conductor sheets discharge electricity because being exposed to the air taken in from outside of the respirator, but the filter is expected to maintain charged status if the charging speed is kept higher that the discharging speed.

For this reason, the capacity of the electrification unit should be decided considering size of the filter unit which may mostly discharge in a high-humidity environment.

The electrification unit is supposed to be enclosed in a damp proof bag and sealed with dry air, but by enclosing a desiccant, the bag can be openable with a plastic fastener such as zip lock. It enables disassembly and maintenance of the electrification unit.

Summary of the Virus Blocking Respirators

Practical application of "Ultra High Performance Filter Respirator" and "Air Flow Electrification Respirator"

View

Regarding effectiveness, feasibility and required period, we anticipate as follows:

The "Ultra High Performance Filter Respirator" can be realized almost in a short time, almost depending on the production system.

"Air Flow Electrification Respirator" is a slightly long-term development because it requires data collection and verification.

In the situation that even simple cloth masks are not produced and supplied sufficiently, it may be difficult to develop new products like this, but we believe in the medium to long term they become reliable and strong measures that prevent the spread of COVID-19 and overcome the issue. Even if they are supplied only for official and medical people, the benefit for entire society would be huge.

These are in patent pending state, but we would like to attach great importance to effectiveness for social benefit and speed for practical application. For this reason, we are currently looking for partners to attend along with open innovation, etc. (details are at the end of the page)

Infection prevention - HVAC system

Airborne Infection Prevention Technology

We have special theories/technology on airborne infection prevention. See detail pages

Summary and manuals are available in PDF

For those who are new to us, please see the easy-to-understand materials first!

Other technology and comments

We infer in any countries in the world, an infection could explode in a building that constantly uses a HVAC (heating, ventilating and air conditioning) system that includes return air (a method that recovers indoor air to reheat to resupply across among rooms/areas).

In fact, in countries / regions (especially in public spaces) and seasons that do not rely heavily on air conditioning, the speed of infection may be reduced (aside from countries that stopped the spread of infection due to initial response, etc.).

Therefore, we would like to propose methods for preventing the spread of infection through HVAC system, and conversely, methods for constructing an air conditioning system that actively disinfects bacteria.

Therefore, we would like to propose methods for preventing the spread of infection via HVAC system, and conversely, methods for constructing an HVAC system that actively sterilizes bacteria.

In addition, we would like to propose the necessary (effective or preferable) environment improvement,in terms of infection prevention, for offices etc. for the quick restart of business activities of companies and organizations.

In addition, we are happy if it would be a good help for people working at government offices and other offices that are already forced to work in the office.

View

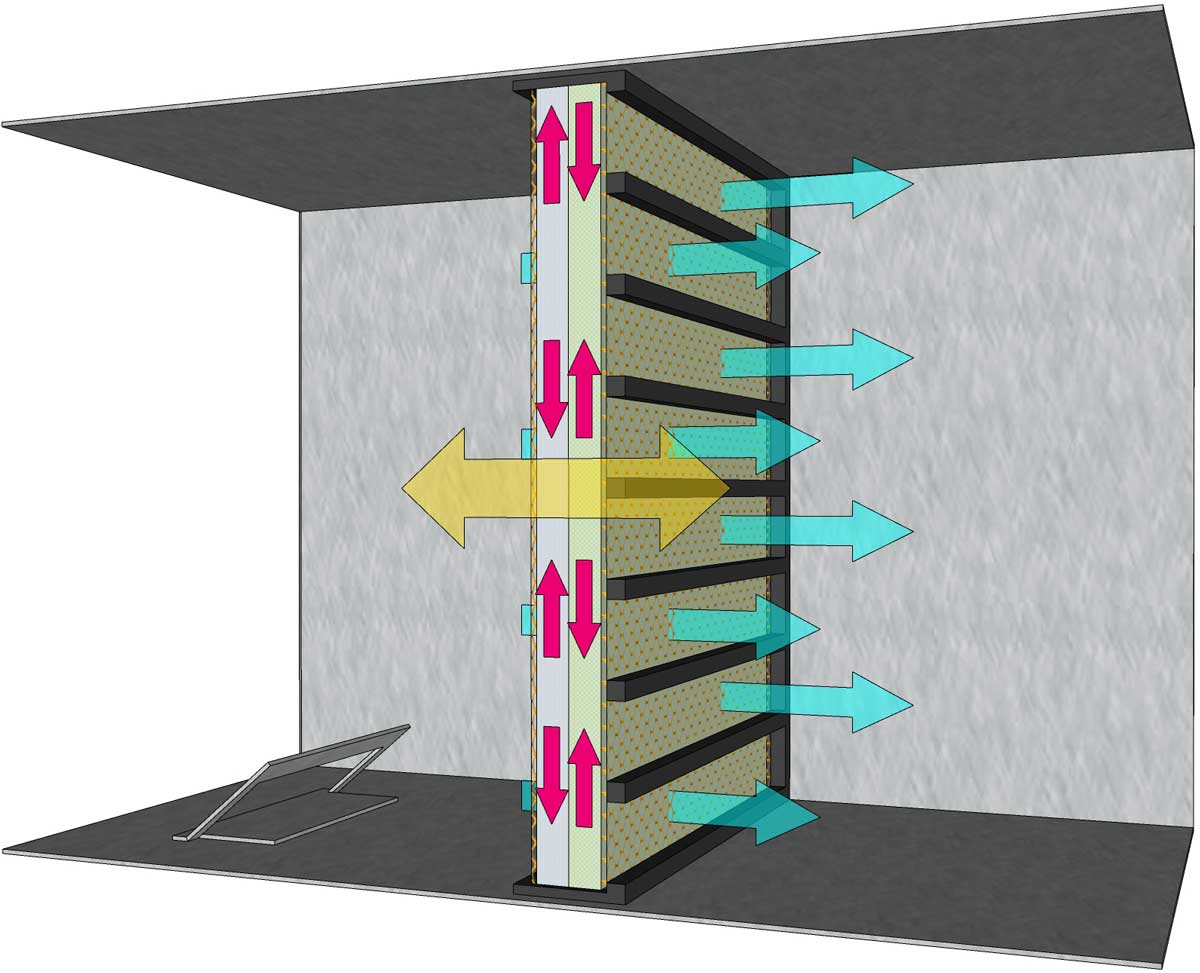

Replacement Air Conditioning

This is an air conditioning system usually applied to clean rooms.

In most cases, supply air (SA) from under the floor and exhaust air (EA) from the ceiling. The air warmed by the body temperature of the person in the room and the exhaust heat from the PC and other equipment naturally rises. By adopting such an air conditioning and ventilation system, the contaminated air and exhaust heat can be removed and replaced with fresh air from the air conditioner efficiently.

However, it is necessary to plan the air outlet on the floor so that it will not be splashed by the infected person's cough or sneeze.

Spot Replacement Air Conditioning

We propose HVAC system that prevents the spread of infection by spot-exhausting the surroundings of each person in the building (occupants) in combination with simple partitions, like draft chambers.

It is Basically additional installation while utilizing the existing air conditioning system.

Temporarily installed with a fan, a simple air intake of exterior air (OA) and a pass duct, exhaust ventilation systems can be constituted. In addition to it, concentrating supply air (SA) from the air conditioning system (maybe existing) to the people in the room in task-ambient way, an HVAC system without resupplying return air can be realized, which reduces the risk of infection in the building (indoors).

(sorry, continuing English article is in preparation)

Air Flow Electrification Filter

Like the "Ultra High Performance Filter Respirator", it utilizes the energy of the pressure fluctuation of the air flow to generate static electricity, which charges the filter and adsorbs particles including viruses.

Seeking partners through open innovation, etc.

View

We are looking for partners to promote R & D and practical application, concerning the technology described in this page, by taking advantage of the expertise of specialists and manufacturers crossing the boundaries of fields through open innovation, etc. In particular, we need business support and specialized knowledge and resources in the following areas.

- Respirators (N95 or higher and special types)

- Air filters (fiber processing technology, etc. for high-performance and safe use for respirators)

- Air filter (general to ultra high performance, for R & D of infection preventing HVAC filter system)

- Static electricity (theoretical / industrial)

- Microfibers, synthetic fibers (especially filters, masks, dusters)

- Sterilization (UV)

- Electric dust collector (small size), air purifier

- HVAC (general)

Since our technical proposals herein include seeds that are in the process of intellectual property, and due to social recognition and high demand, we anticipate smooth fund raising and sufficient business feasibility can be expected for each party. Therefore, we believe that you could participate in earnest without anxiety of hindering your business.

Currently, many companies and organizations are forced to suspend their activities, but we look forward to hearing from such parties. Let's work together to save the world from a pinch of coronavirus infection!

Inquiries

Please contact us from here